Original Lighting Solution

Two lighting system types were employed for the storage room illumination: the 2-tubes lights with thin high-brightness flourescent tubes (T5 diameter, 1,500 mm of lenght) were installed in common areas and spaces between racks. The gas-discharge lamps (400 W each) were employed for the wrapping and cargo areas illumination in order to meet the lighting quotes for these area types.

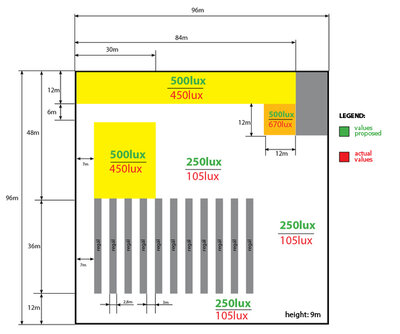

There were 424 2-tubes light units (848 tube units) and 52 gas-discharge light units at 9 m elevation in whole area of 96 x 96 m. According the project, the light intensity should be 500 lux in "yellow areas" and 250 lux in "white areas", as stated in green. Unfortunatelly, the real values were different. During the audit carried on in the night (in order to avoid the light entering throught the ceiling transoms) we obtained values (in red) generaly lower than stated in project.

New Lighting Solution:

New LED High Bay Lights, a model 100A-320, were chosen as the most effective and the cheapest LED Lighting solution.

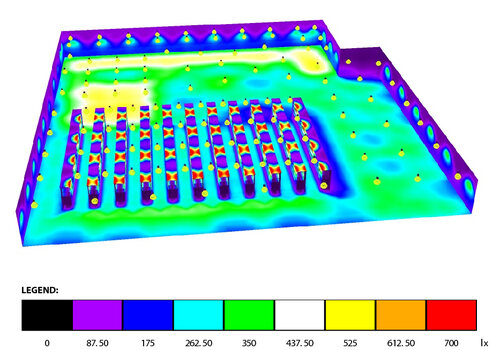

Whole lighting units amount could be reduced from 476 original units into 117 new units thanks to these high brightness LED lights. As visible on 3D model visualization, a new LED lights raster was elaborated.

Due to the 9 m heigh of the hall, further lighting intensity enhancement was ensured by use of 90° beaming angle. Therefore, the light intensity was increased by 20~30% while output remained unchanged.

Consequently, the calculation was carried once again. It shows a light distraction in the space and corresponding lighting values (lux).

The average value is E(av) =283 lux, while maximum lighting values reach E(max) = 527 lux. 3D visualization in colour the corresponding lighiting zones are visible.

Total Lighting Cost Reduction

The project application brought the reduction of energy consumption 258 MWh per year, what means the energy costs were reduced by 46%. The customer saved 33,750 € per year and the return on investment was only 2.3 years.

The average LED Lights operation time is 50,000 hours, what in this case (regarding the frequency and illumination period) means 6.4 years. Total cost reduction estimated during the lighs operation time can reach 216,000 €.